Parco Innovation products Slow Speed granulator

GSL180.UK

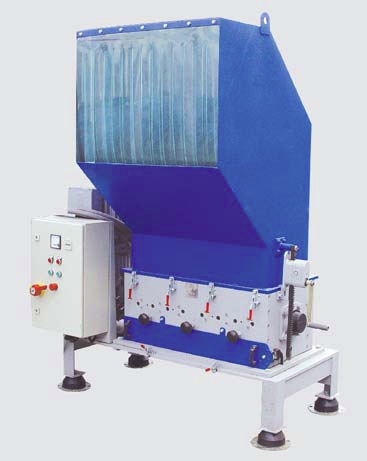

Slow speed granulator small model GSL180

Slow speed granulator of the

GSL180/120-180/430 range were designed more particularly for applications in the field of injection.

Strong construction et designed for easy cleaning.

After sharpening no adjustment is necessary for reassembly.

Characteristic:

Granuling chamber : 120 x 270 mm to 430 x 270 mm

Rotor : diameter 180 mm

Blades : 12 to 48 movable blades

Adjustment : no adjustment after sharpening

Hopper : straight, angled or special

Chassis : bottom with suction tray, top to empty in bag

Motor : 2.2 to 4 kW, 400 V - 50 Hz – three-phase

Electric : in compliance with the current standard VDE

Option :

Loading conveyor with or without metal particle detection tunnel.

Strong construction et designed for easy cleaning.

After sharpening no adjustment is necessary for reassembly.

Characteristic:

Granuling chamber : 120 x 270 mm to 430 x 270 mm

Rotor : diameter 180 mm

Blades : 12 to 48 movable blades

Adjustment : no adjustment after sharpening

Hopper : straight, angled or special

Chassis : bottom with suction tray, top to empty in bag

Motor : 2.2 to 4 kW, 400 V - 50 Hz – three-phase

Electric : in compliance with the current standard VDE

Option :

Loading conveyor with or without metal particle detection tunnel.

GSL300.UK

Big slow crusher models GSL300

Big slow crusher models GSL300:

GSL300 / 400-300 / 800

s with slow speed of the range GSL 300/400 - 300/800 were more particularly designed for uses in the field of the injection and the small flasks.

Construction strong and studied for an easy(well-to-do) cleaning.

After the sharpening no regulation is necessary for the reassembly.

Characteristics:

Chamber(Room) of grinding: 400 x 400 mm in 400 x 800 mm

Rotor: diameter 300 mm

Blades: 33 in 66 mobile blades.

Regulation: no regulation after sharpening.

Hopper: straight(right), oblique or special

Frame: low with tub(ferry,high school diploma) of inhalation(pursuit), Turbine for draining in bag.

Engine: 7.5 in 18 kW, 400 V - 50 Hz - three-phase

Electric: in compliance with the current standard VDE.

Options:

Conveyor of load with or without tunnel of detection of particles

GSL300 / 400-300 / 800

s with slow speed of the range GSL 300/400 - 300/800 were more particularly designed for uses in the field of the injection and the small flasks.

Construction strong and studied for an easy(well-to-do) cleaning.

After the sharpening no regulation is necessary for the reassembly.

Characteristics:

Chamber(Room) of grinding: 400 x 400 mm in 400 x 800 mm

Rotor: diameter 300 mm

Blades: 33 in 66 mobile blades.

Regulation: no regulation after sharpening.

Hopper: straight(right), oblique or special

Frame: low with tub(ferry,high school diploma) of inhalation(pursuit), Turbine for draining in bag.

Engine: 7.5 in 18 kW, 400 V - 50 Hz - three-phase

Electric: in compliance with the current standard VDE.

Options:

Conveyor of load with or without tunnel of detection of particles

HEL100.UK

Serie 100

Width

97 mm

Diameter of rotor

100 mm

Engine power

0,75-1,1 kW

Number of movable knives

3

Number of fixed knives

2

Cutting speed

160 t/min

Weight

Env. 40 kg

Crushing rate

Env. 3-12 kg/h

Dimensions (L x w x h)

220 x 303 x 750 mm

97 mm

Diameter of rotor

100 mm

Engine power

0,75-1,1 kW

Number of movable knives

3

Number of fixed knives

2

Cutting speed

160 t/min

Weight

Env. 40 kg

Crushing rate

Env. 3-12 kg/h

Dimensions (L x w x h)

220 x 303 x 750 mm

HEL150.UK

Serie 150

Width

120 / 230 / 340 mm

Diameter of rotor

150 mm

Engine power

1,5-4 kW

Number of movable knives

3

Number of fixed knives

2

Cutting speed

280 t/min

Weight

Env. 170-250 kg

Crushing rate

Env. 10-50 kg/h

Dimensions (L x w x h)

440-638 x 800 x 1250 mm

120 / 230 / 340 mm

Diameter of rotor

150 mm

Engine power

1,5-4 kW

Number of movable knives

3

Number of fixed knives

2

Cutting speed

280 t/min

Weight

Env. 170-250 kg

Crushing rate

Env. 10-50 kg/h

Dimensions (L x w x h)

440-638 x 800 x 1250 mm